As a rule of thumb the jacket pressure will be governing when internal pressure of vessel is less than 167 times the jacket pressure. The dimple jackets are generally limited to 300 psig design pressure while half coil jackets can be used up to a design pressure of 750 psig.

Jacketed Vessel Design

Dimple Jacket Laser Welded As Tank Wall For Process Tanks Buco Htt

Attributes And Uses Of Asme Vessel Heat Transfer Surfaces 2018

Hoop direction stiffeners will develop bending stresses as well.

Dimple jacket design calculation.

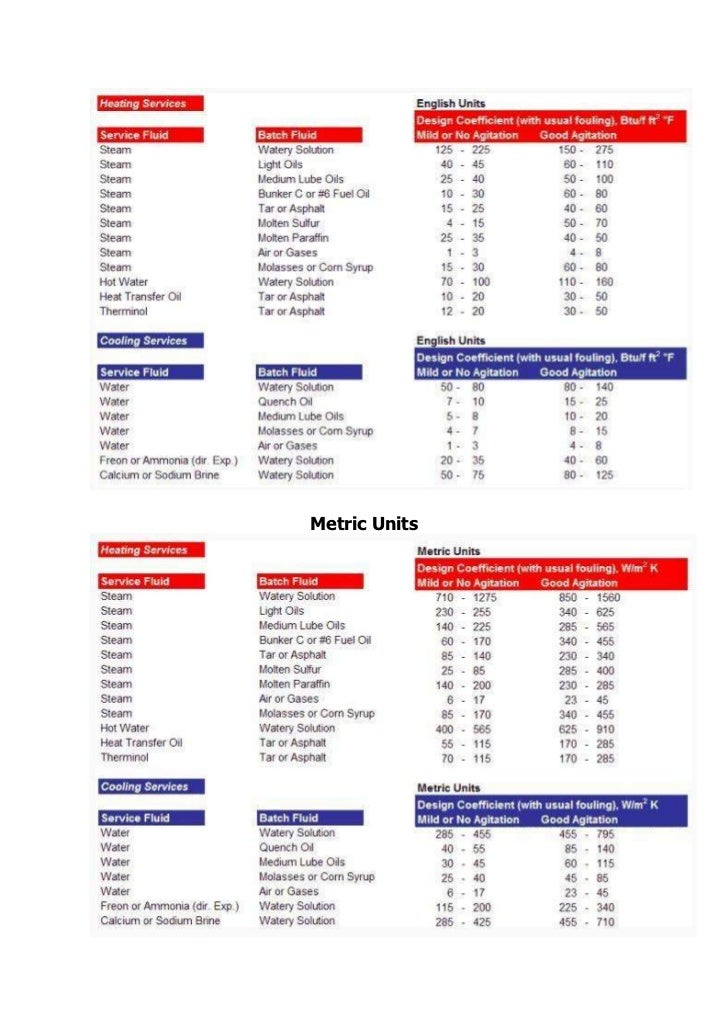

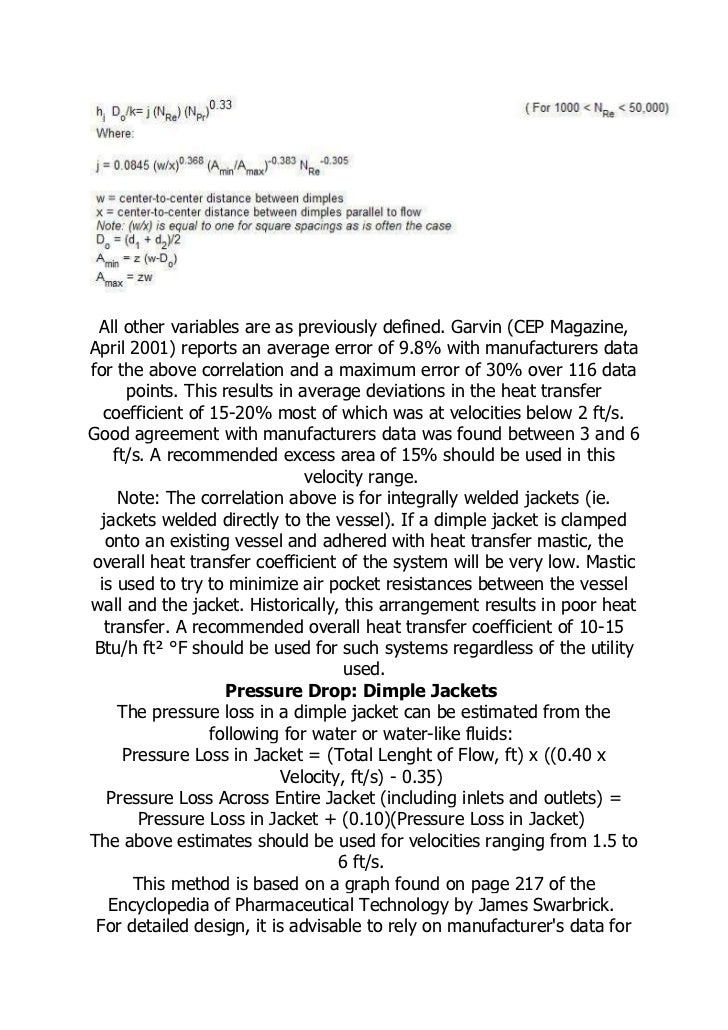

Estimates overall heat transfer coefficient for a vessel with an agitator along with heatingcooling medium flowing in jacket jacket with spiral or half pipe coil.

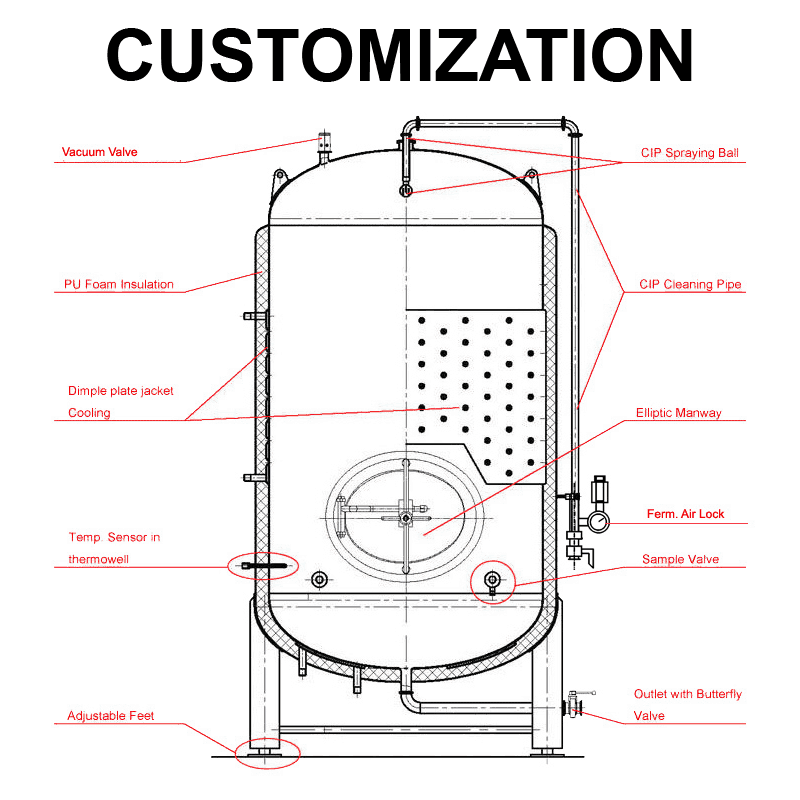

The dimple jacket design provides a large heating or cooling transfer area up to 200 psig.

If the dimple stiffeners run in the axial direction they will try to straighten out and have some very high stresses indeed.

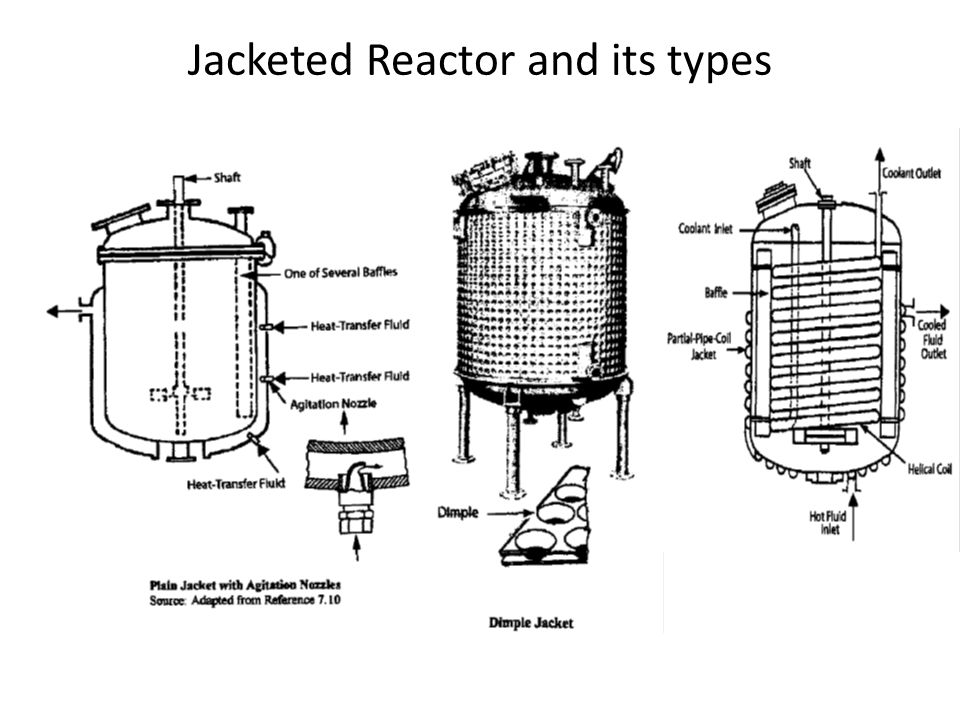

Jacketed vessel design design of dimple jackets jacketed vessel design design of dimple jacketsthe design of dimple jackets permits construction from light gaugemetals without sacrificingthe strength required to withstand the specified pressure.

This results in considerable cost saving as compared to convention jackets.

On large tanks dimple jackets have a lower price point and maintain a higher.

I presume the dimples run in the circumferential direction if so they should act as a flange or ring stiffener by providing section depth.

The design of dimple jackets permits construction from light gauge metals without sacrificing the strength required to withstand the specified pressure.

For half pipe coil jacket the higher heat flux rate may require multiple sections of jackets to avoid having condensate covering too much of the heat transfer area.

Medium which is passed through a jacket that surrounds the section of the vessel containing the liquid.

Dimple jacket technology is not limited to tanks.

Chemical engineering calculations to assist process plant operation and maintenance engineers.

Dimple jackets are very versatile.

These dimples impart turbulence to the heating or cooling media as it flows through the jacket.

Is the inner shell attached to the outer jacket.

A thin external shell is affixed to the vessel shell with laser welds located in a regular pattern.

Often about 50mm on centre both horizontally and vertically.

At such conditions dimple jackets are typically more.

This resultsin considerable cost saving as compared to convention jackets.

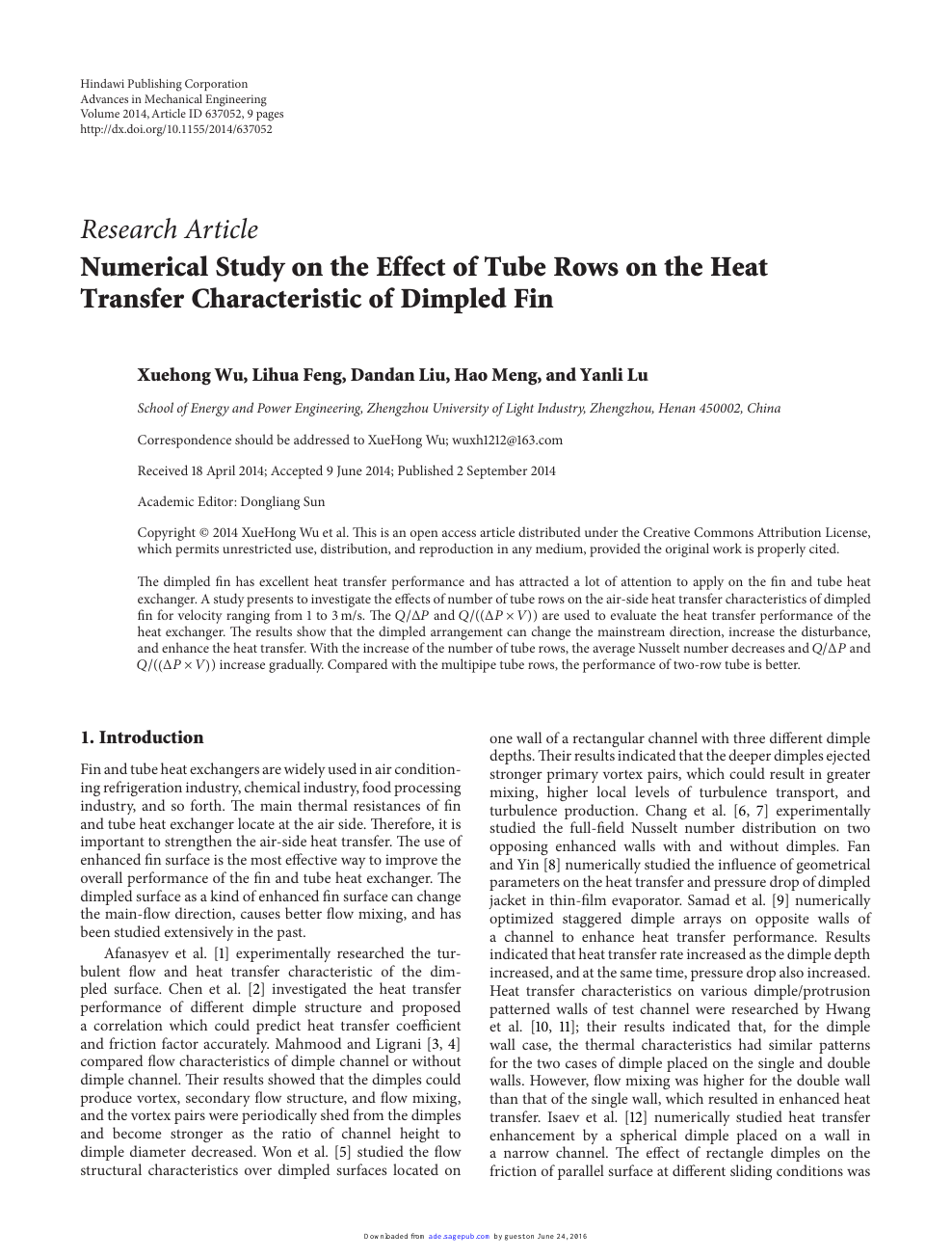

Design calculation begin with an assumed flow velocity between 2 and 5 fts.

For low pressure steam services convention jackets are a much more economical choice.

Saturated steam is indicated in this example as the heating medium.

High heatingcooling transfer is possible.

They can be used to provide heat transfer or cooling for virtually any shape or size of vessel.

Figure 2 represents an arrangement for cooling a batch liquid by a non isothermal medium which is passed through a jacket that surrounds the section of the vessel.

Designcalculation begin with an assumed flow velocity between 2 and 5 ftsas a rule of thumb the jacket pressure will be governing when.

Jacketed vessel design 1.

Benefits Of Dimple Jackets For Pressure Vessels Highland Equipment

Dimple Jacket Design Calculation Yaser Vtngcf Org

Jacketed Vessel Design Calculus En5kkwemmpno

China Reaction Vessel With Dimple Jacket China Reaction Vessel

Jacketed Vessel Design Docx Document

Jacketed Vessel Design Heat Transfer Steam

Http Pvmanage Com Wp Content Uploads 2018 12 General Design Part3 Pdf

Chemical Polymer Reactor Design Ppt Download

China Dimple Jacket Reactor Direct Manufature Price China Dimple

Volume Vi Iii Avoid Costly Design Mistakes Boardman Llc

Pta 5000 Customization Pressure Tanks 1001 5000l

Jacketed Vessel Design

Dimple Jacket Design Calculation Yaser Vtngcf Org

External Pressure Pressure Vessel Engineering

Jacketedvesseldesign 111205043420 Phpapp01 1 Heat Transfer Heat

Jacketed Vessel Design

Pramukh Design Consultancy

Overall Heat Transfer Dimple Heat Transfer Surface Holloway

Jacketed Vessel Design

Dimple Jacket Laser Welded As Tank Wall For Process Tanks Buco Htt

Tank Coils

External Pressure Pressure Vessel Engineering

Pdf External Pressure Calculations Anand Raj Academia Edu

Dimple Jacket Pressure Drop Deconeq Engineering Group

Dimple Jacket Pressure Drop Deconeq Engineering Group

Https Epubl Ktu Edu Object Elaba 16249312 16249312 Pdf

Https Avestia Com Htff2014 Proceedings Papers 99 Pdf

Https Www Chemicalprocessing Com Assets Wp Downloads Pdf Cp1303 Pickheaters Jacketed Heating Final Pdf

Http Www Gmp1st Com Index Php Ci Id 14656 La Id 2 Htm

Volume Vi Iii Avoid Costly Design Mistakes Boardman Llc

Heat Transfer Tank Components Paul Mueller Company

Jacketed Vessel Design For Cooling Heating By Anderson Dahlen

Dimple Jacket Pressure Drop Deconeq Engineering Group

Http Pvmanage Com Wp Content Uploads 2018 12 General Design Part3 Pdf

Process Pressure Vessel Shabani Engineering

External Pressure Pressure Vessel Engineering

Dimple Jacket Design Calculation >>>>> Download Now

ReplyDelete>>>>> Download Full

Dimple Jacket Design Calculation >>>>> Download LINK

>>>>> Download Now

Dimple Jacket Design Calculation >>>>> Download Full

>>>>> Download LINK